How to avoid the cutting burr:Charry

How to avoid the cutting burr

How to avoid the cutting burr.

In the process of sheet metal processing, the gas purity and parameter setting of the laser cutting machine will affect the final processing effect. Adjust the equipment + gas + parameters to the best, and the cut work piece is free of burrs.

Why there is the cutting burr?

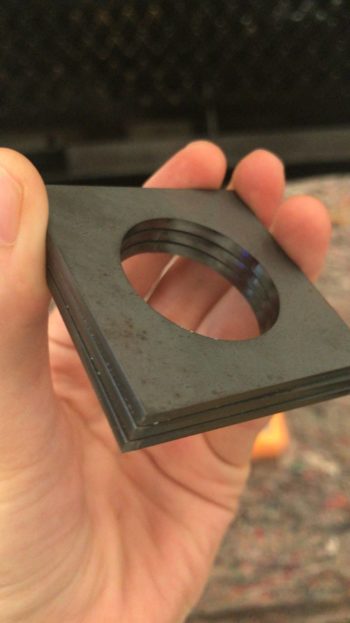

In fact, burrs are excessive residue particles on the surface of metal materials. When the laser cutting machine is processing the work piece, the high energy generated by the laser beam illuminating the surface of the work piece causes the surface of the work piece to rapidly vaporize and evaporate to achieve the purpose of cutting. But here is a core device that we must pay attention to is the auxiliary gas.

The auxiliary gas is the slag that blows off the surface of the work piece after the surface of the work piece is vaporized. If the auxiliary gas is not used, the slag is cooled and a burr is formed on the cutting surface. The purity of the gas is high, and it can be exchanged for a gas supplier with better quality. The purity of the gas is very important. It is best not to use the cylinder gas, because after two fillings, the purity is not good and the gas is wasted.

Another reason is the quality of the equipment itself, as well as the parameter setting factors, so when the customer purchases the laser cutting machine, the professional operator must debug the equipment. Adjusting the cutting parameters to the best, the speed of the pneumatic flow focal length cutting, or so many adjustments, the parameters provided by the machine can not cut the delicate work piece.

If a material has a burr, then the material can be qualitatively defective. The more burrs, the lower the quality naturally.

How to avoid the cutting burr?

1. The upper and lower positions of the focus of the beam is not correct.

Solution: Adjust the position of the focus and adjust it according to the offset position it produces.

2. The output power of the laser cutting machine is not enough.

Solution: Check if the laser cutter is working properly. If it is not normal, it needs timely repair and maintenance. If it is normal, check if the output value is correct.

3. The cutting speed of the cutting machine is too slow.

Solution: Adjust and increase the wire cutting speed in time.

4. The purity of the auxiliary gas of the cutting machine is not enough.

Solution: Explain the increase in the purity of the auxiliary gas.

5. The addition of the laser beam of the cutting machine is offset.

Solution: Debug the focus and make adjustments in time.

6, the laser cutting machine operating time is too long and the instability.

Solution: Turn off the machine and let the machine rest.

If you want to know more,contact us.

Whatsapp:+8618253165863