Introduction of fiber laser cutting machine for metal–Max

Product Application

metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry.

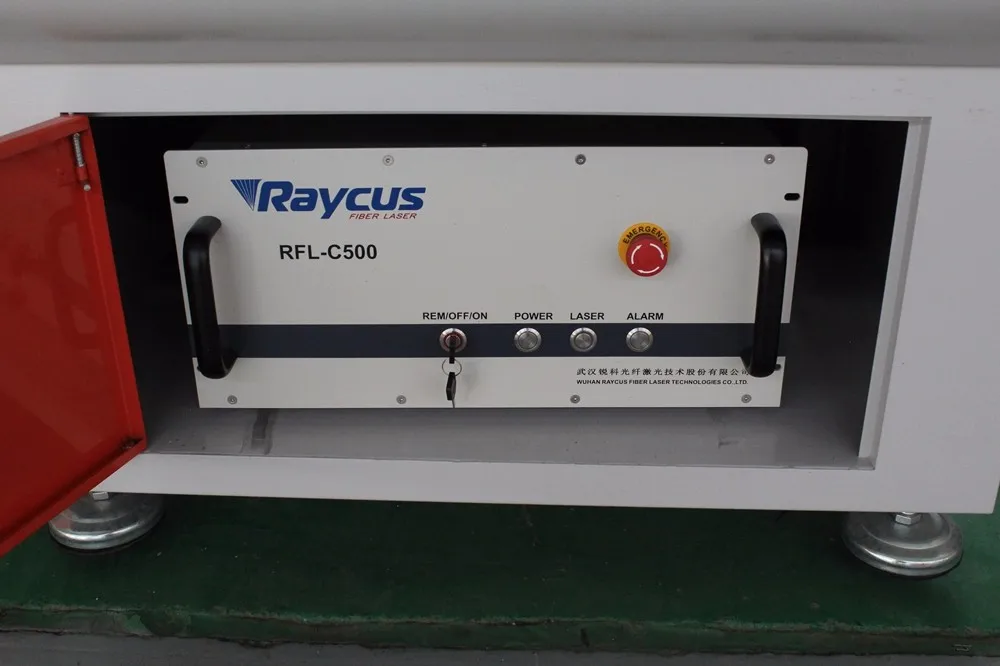

Cutting samples

Main Features

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: 2-3 times than same power CO2 laser cutting.

3. Stable running: adopt top world import fiber lasers, stable performance, working times 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have 3 times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

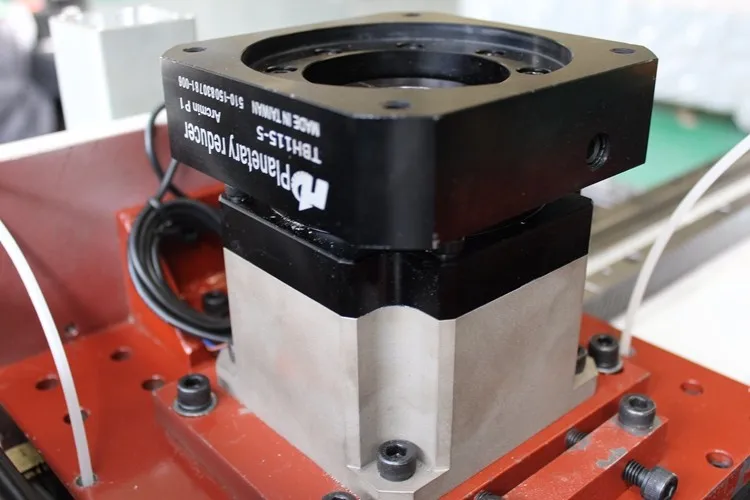

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7 Easy operations: fiber line transmission, no adjustment of optical path.