How Fiber Laser Cutting Machine Works?-Angelina

How Fiber Laser Cutting Machine Works?

Fiber laser cutting machine is a currently popular laser cutting type.

It adopts fiber laser source to fulfil perfect cutting effect.

Fiber lasers are a type of solid state laser that is rapidly growing within the metal cutting industry.

Fiber technology utilizes a solid gain medium, as opposed to a gas or liquid.

The “seed laser” produces the laser beam and is then amplified within a glass fiber.

Fiber laser source can outputs high-powered laser beam that focuses on the surface of materials, vaporizing or melting the focused area instantaneously.

Fiber laser cutter has been developed into a highly precise laser cutting type.

People used it widely in metal parts processing industries.

1.Work Versatility of Fiber Laser Cutting Machine for Metals

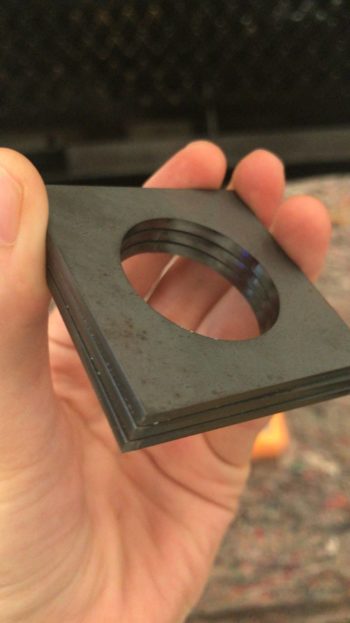

Fiber laser cutting machine is able to process a wide range metal materials.

It includes stainless steel, carbon steel, alloy steel, aluminum, galvanized sheet, copper, silver, gold and so on.

Regarding to the features of metals,we could opt different fiber laser sources.

In addition to sheet metals cutting, fiber laser cutting machine also could process profiled metals and steel pipes.

Also a set of steel pipe cutting system can be configured to the machine to broaden its cutting capacity.

Besides,the cutting edge is neat and smooth to meet high industrial requirement.

2.Main Advantages of Fiber Laser Cutting Machine

- Fiber laser has higher energy conversion rate that can reach up to 30%, saving operation and maintenance cost.

- We design Fiber lasers with semiconductor modular and redundancy, and there is no optical lens in resonant cavity. So no need to spend much time starting and adjusting the machine before cutting work, which is incomparable among traditional laser machines.

- Laser head won’t touch the materials directly so as not to scratch the materials and ensure quality cutting effect.

- Fiber laser produces the smallest kerf and thermal area, which keeps the cutting stability and avoid deformation of the material.

- 02mm/min cutting accuracy and fast cutting speed markedly increases the work efficiency of metal parts manufacturing.

- Fiber laser cutting machine works in a safe and environmentally friendly way. Little pollution and noise and workshop environment protection.